SLS materials with high performance guaranteed

SLS composite materials Windform® TOP-LINE are for Selective Laser Sintering (SLS), an Additive Manufacturing technique that uses a laser as the power source to sinter powdered material from a 3D model. This process does not require tooling to manufacture parts. It is ideal to produce tough, functional parts or prototypes, with the possibility to achieve excellent surface finish and fine detailing.

Prevalent SLS materials are thermoplastic polymers.

Windform® TOP-LINE SLS materials are engineered to offer full range of options, possibilities and features, from excellent thermal properties to resistance to high temperature, from high stiffness and excellent strength to reduced weight, just to name a few.

They are used for functional prototypes and end-use components for the most highly demanding industries.

Windform® TOP LINE SLS materials High-Performance features

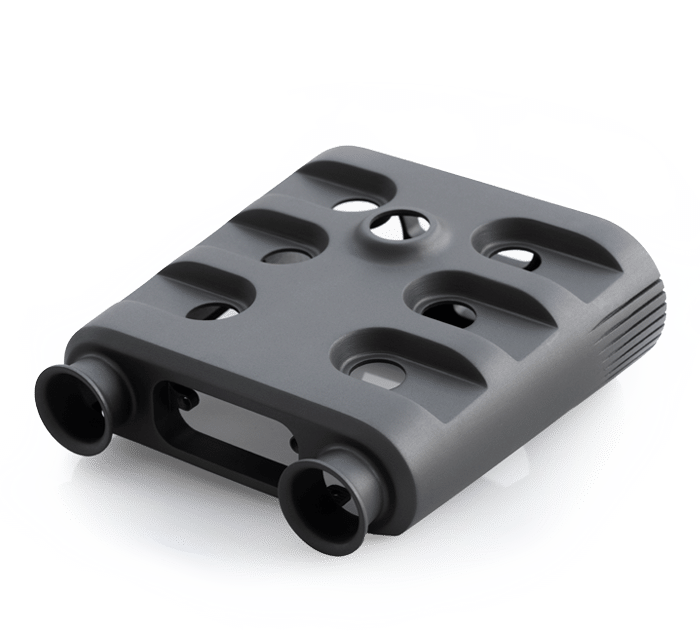

Strength and Lightness

Windform® TOP-LINE composite materials can also be used to create internal truss structures. Lightness, strength and stability are the main benefits.

Reticulated structure can be used in several applications, where weight reduction and high stability are required, especially for the industries of Aerospace, Unmanned Aerial System, Motorsport and Automotive.

Space-ready

Windform® TOP-LINE SLS materials are known as advanced materials for satellite and space exploration programs, conforming to VUV testing and to strict NASA and ESA standards for outgassing.

Windform® materials perform in the harshest environments and have been contributed to the success of some of the most important space missions for smallsats.

See NASA results and ESA results.

Photo credits: Copyrighted 2014. TechMedia Network. 107965:114DS

CNC Machining

With CNC machining it is possible to bring tolerance down to hundredths of millimeter in case of tight specifications requested.

Windform® parts can be CNC machined with 5-axis milling centers and with lathes in order to have complex and highly accurate features.

Moreover, the combination of industrial 3D printing and high precision CNC machining leads to speed up the manufacturing process of the parts and save time.

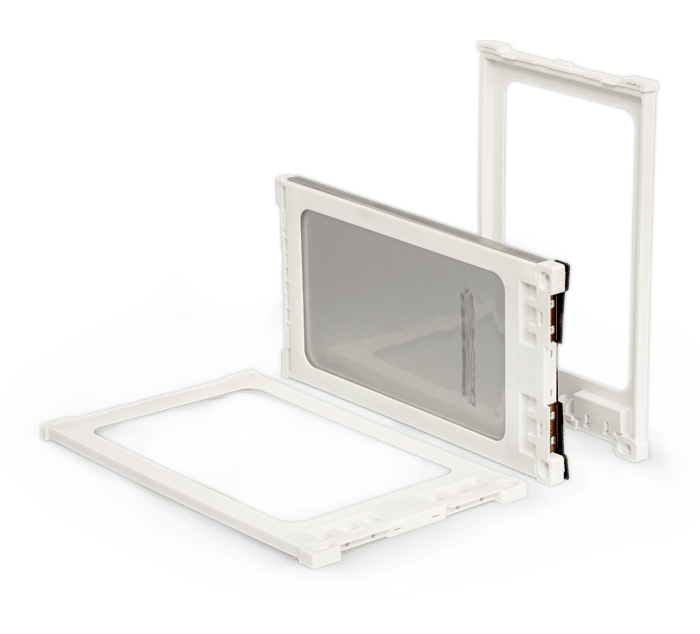

Waterproof

Waterproofing is vital for many purposes and even more applications from the most demanding sectors – especially motorsport, automotive and medical – required to be waterproof.

Among Windform® TOP-LINE family of composite materials, Windform® SP and Windform® GT are waterproof materials.

They are resistant to absorption of liquids (water, oil, gasoline, etc…), moisture and gas.

Skin Contact Approved

Many Windform® TOP-LINE Selective Laser Sintering materials have passed both the patch epicutaneous test and the analysis performed on the leaching liquid.

The tests are to assess and gauge the compatibility with the human skin as absence of skin irritation.

The results show that they can be used to create devices which can be applied on skin. Moreover, thanks to the mechanical features of all Windform® TOP-LINE materials, they can be used to create 3D printed breathable prototypes and parts.

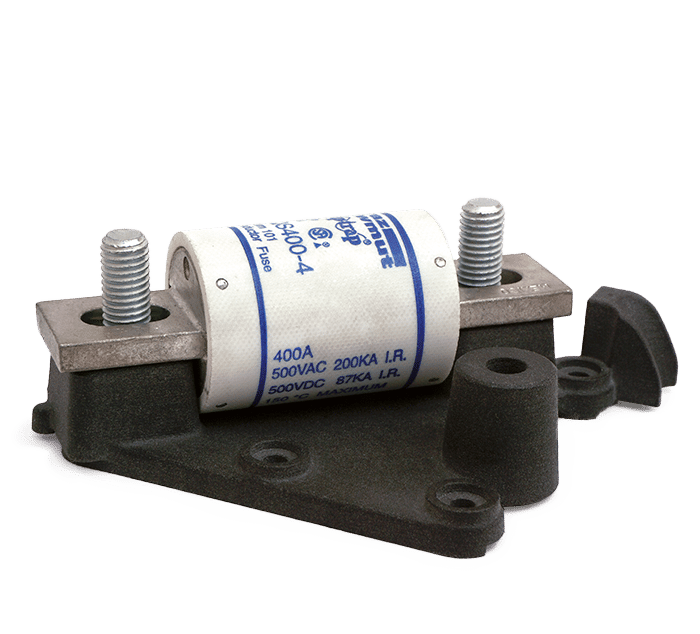

Electrical Insulation

Many Windform® TOP-LINE composite materials are non-conductive electrically materials so they are suitable for electronic applications, such as electronic control units components, electrical connectors and any prototypes in touch with electronic items.

This is proved by the Comparative Tracking Index (CTI) equal to 600, maximum test voltage.

The CTI is used to measure the electrical breakdown properties of an insulating material. The better the insulation, the higher the CTI: a higher CTI value means a lower minimum creepage distance required, and the closer two conductive parts can be.

Flammability

Many Windform® TOP-LINE SLS materials have been tested for their flammability rating.

They have been rated HB according to the flammability UL 94 test.

Windform® family also includes Windform® FR1, the unique Flame Retardant (V-0 rated) material for Additive Manufacturing Carbon fiber reinforced.

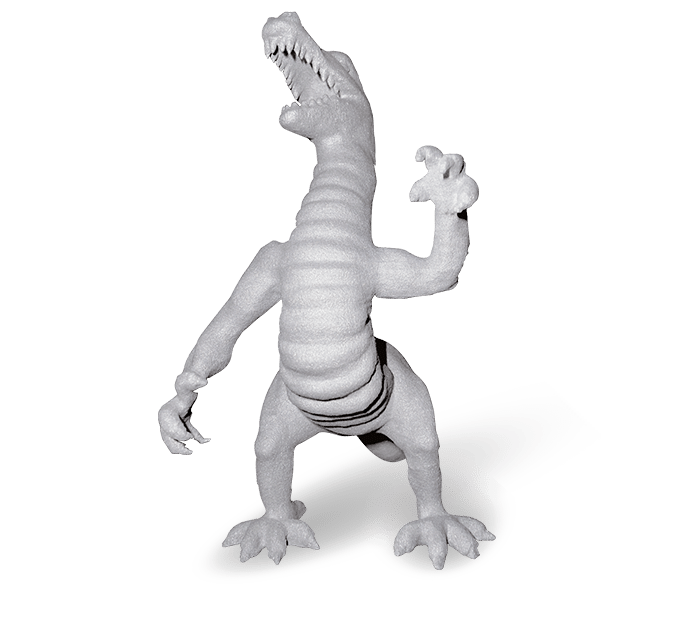

Selective Laser Sintering technology at a glance

SLS stands for Selective Laser Sintering, an important 3D printing technology where a special powdered polyamide material is sintered with an infrared laser at elevated temperatures consolidating the powder grains: the part is made by consecutive overlapping of layers.

The process consists of a so-called “bed” on which the roller spreads a thin layer of powder followed by sintering according to the layers sliced from a 3D model file.

Due to this, SLS belongs to the so-called Powder Bed Fusion technologies (PBF).

The technology doesn’t require any support because the piece is held up by the non sintered powders avoiding the need of a structure and making it ideal to 3D print complex designs that would otherwise require printing in multiple parts.

The beauty of SLS technology leans on its ability to be a reliable, and fast method that has defied the test of time