Class of Material

Glass fiber filled composite material polyamide based

Technology

Selective Laser Sintering

FEATURES

Electrical insulation materialExcellent surface finish in its sintered stateSimilar resistance to impact at room and low temperatureSkin contact approved

KEY VALUES

Density (20° C) 1,324 g/ccHDT (1.82 Mpa) 175,9° CTensile Strength 60,42 MpaComparative Tracking Index 600After manual finishing 3,2 Ra μm

APPLICATIONS

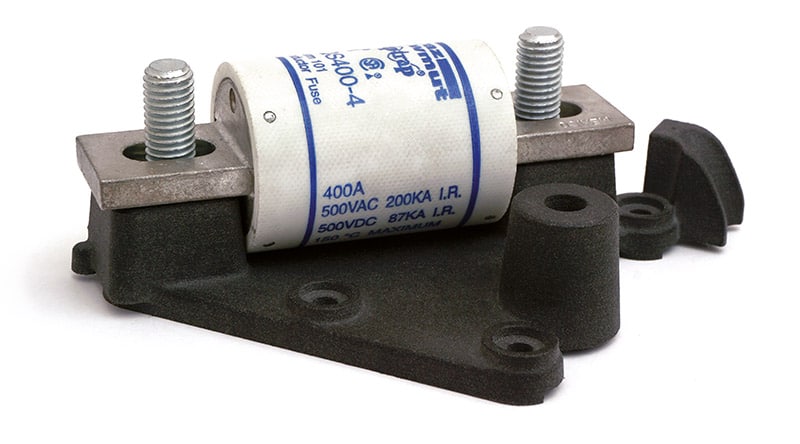

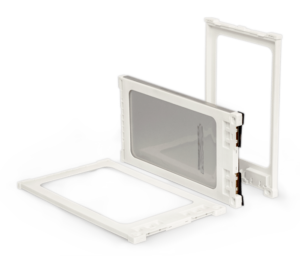

Boxes, containers of electrical and electronic componentsComplex parts and assembly testingConnectors, driver cockpit componentsCooling/ducted fans, UAV structural componentsCovers, latching systems, air intake systems

FEATURES

Electrical insulation materialExcellent surface finish in its sintered stateSimilar resistance to impact at room and low temperatureSkin contact approved

Which characteristics

are you searching for?

KEY VALUES

Density (20° C) 1,324 g/ccHDT (1.82 Mpa) 175,9° CTensile Strength 60,42 MpaComparative Tracking Index 600After manual finishing 3,2 Ra μm

Technical data sheet

DownloadAPPLICATIONS

Boxes, containers of electrical and electronic componentsComplex parts and assembly testingConnectors, driver cockpit componentsCooling/ducted fans, UAV structural componentsCovers, latching systems, air intake systems

Windform successful stories

Get inspiredTechnical Properties

Density: 1,324 g/cc

Colour:

BLACK

| Thermal Properties | Test Method | SI Unit | US Unit |

|---|---|---|---|

| Melting point | ISO 11357 | 183,3° C | 361.94° F |

| HDT, 1.82 Mpa | ASTM D 648 TYPE B | 175,9° C | 348.62° F |

| Vicat 10N | ASTM D1525-09 | 178,8° C | 353.84° F |

| Flammability Properties | Test Method | SI Unit | US Unit |

|---|---|---|---|

| Burning Test - HB 1 mm | UL 94 | HB | HB |

| Burning Test - HB 3 mm | UL 94 | HB | HB |

| Mechanical Properties | Test Method | SI Unit | US Unit |

|---|---|---|---|

| Tensile Strength | UNI EN ISO 527-1 | 60,42 Mpa | 8763.18 psi |

| Tensile Modulus | UNI EN ISO 527-1 | 6048 Mpa | 877.18 ksi |

| Elongation at Break | UNI EN ISO 527-1 | 2,42 % | 2.42 % |

| Flexural Strength | UNI EN ISO 14125 | 85,80 Mpa | 12444.23 psi |

| Flexural Modulus | UNI EN ISO 14125 | 5465,20 Mpa | 792.66 ksi |

| Impact Strength Unnotched (Charpy 23°C - Completely broken specimens) | UNI EN ISO 179-1 | 18,82 KJ/m² | 8.95 ft-lb/in² |

| Impact Strength Notched (Charpy 23 °C/73.4 °F) | UNI EN ISO 179-1 | 5,33 KJ/m² | 2.53 ft-lb/in² |

| Impact Strength Notched (Charpy -40 °C/-40 °F) | UNI EN ISO 179-1 | 4,83 KJ/m² | 2.29 ft-lb/in² |

| Hardness Shore D | UNI EN ISO 868 | 80 | 80 |

| Compression Strength | ASTM D695-10 | 97,8 Mpa | 14184.69 psi |

| Compression Elastic Modulus | ASTM D695-10 | 4,50 Gpa | 652.67 ksi |

| Electrical Properties | Test Method | SI Unit | US Unit |

|---|---|---|---|

| CTI Comparative Tracking Index | ASTM D257-14 | 600 | 600 |

| Resistivity, Volume | ASTM D257-14 | 1,7x10^13 ohm*cm | 1.7x10^13 ohm*cm |

| Resistivity, Surface | ASTM D257-14 | 6,8x10^15 ohm | 6.8x10^15 ohm |

| Surface Finish | SI Unit | US Unit |

|---|---|---|

| After SLS Process | 7,5 Ra μm | 7.5 Ra μm |

| After manual finishing | 3,2 Ra μm | 3.2 Ra μm |

| After CNC machining | 1,2 Ra μm | 1.2 Ra μm |

| Properties per Density Unit | SI Unit | US Unit |

|---|---|---|

| UTS per density unit | 45,63 Mpa/(g/cc) | 6618.71 psi/(g/cc) |

| Tensile Modulus per density unit | 4567,98 Mpa/(g/cc) | 662.52 psi/(g/cc) |

| Flexural Strength per density unit | 64,80 Mpa/(g/cc) | 9398.96 psi/(g/cc) |

| Flexural Modulus per density unit | 4127,79 Mpa/(g/cc) | 598.68 psi/(g/cc) |

Note: The material properties provided herein are for reference purposes only. Data was generated from the testing of parts produced with Windform LX 3.0 material under optimal processing conditions. Actual values may vary significantly as they are affected by part geometry and process parameters. Material specifications are subject to change without notice.

Standard Technical Details for Accuracy versus Tolerance:

For parts up to 1 mm (0.039″), the standard tolerance is ± 0,070 mm (0.003″)

For parts up to 3 mm (0.118″), the standard tolerance is ± 0,125 mm (0.005″)

For parts up to 6 mm (0.236″), the standard tolerance is ± 0,150 mm (0.006″)

For parts over 6 mm (0.236″), refer to UNI EN ISO 286-2 JS14 class (linear tolerances).

Technical specifications

Windform® LX 3.0 is a composite polyamide based material reinforced with a new generation glass fiber system.

It is a naturally black material characterized by good tensile strength and stiffness.

Windform® LX 3.0 has improved the already excellent performance of Windform® LX 2.0. These improvements can be noticed from a sinterability standpoint. It maintains the Windform® LX 2.0 technical and thermal properties.

Windform® LX 3.0 is also characterized by high level of temperature resistance (HDT, 1.82 Mpa, is 175,9°C / 348.62 °F) and has been rated HB according to the flammability UL 94 test.

It is also not electrically conductive with CTI 600.

Windform LX 3.0 has passed ESA standard screening outgassing tests for space-flight applications.

Applications

Windform® LX 3.0 is an entry-level SLS material and is perfect for creating functional prototypes or finished parts that require reliability, resistance and aesthetical properties.

Windform® LX 3.0 has an excellent surface finish in its sintered state; it is perfect for components with fine details.

Windform® LX 3.0 is highly recommended for applications that require a strong visual impact and for aesthetical and design parts.

You might be also interested in

Flame Retardant composite polyamide based material glass fiber filled with insulating properties