Class of Material

Carbon fiber filled composite material polyamide based

Technology

Selective Laser Sintering

FEATURES

Excellent strengthHigh stiffnessReduced weightTop level material

KEY VALUES

Density (20° C) 1,097 g/ccHDT (1.82 Mpa) 173,4° CTensile Strength 83,84 MpaElongation @ break 3,80 %Melting point 179,3° C

APPLICATIONS

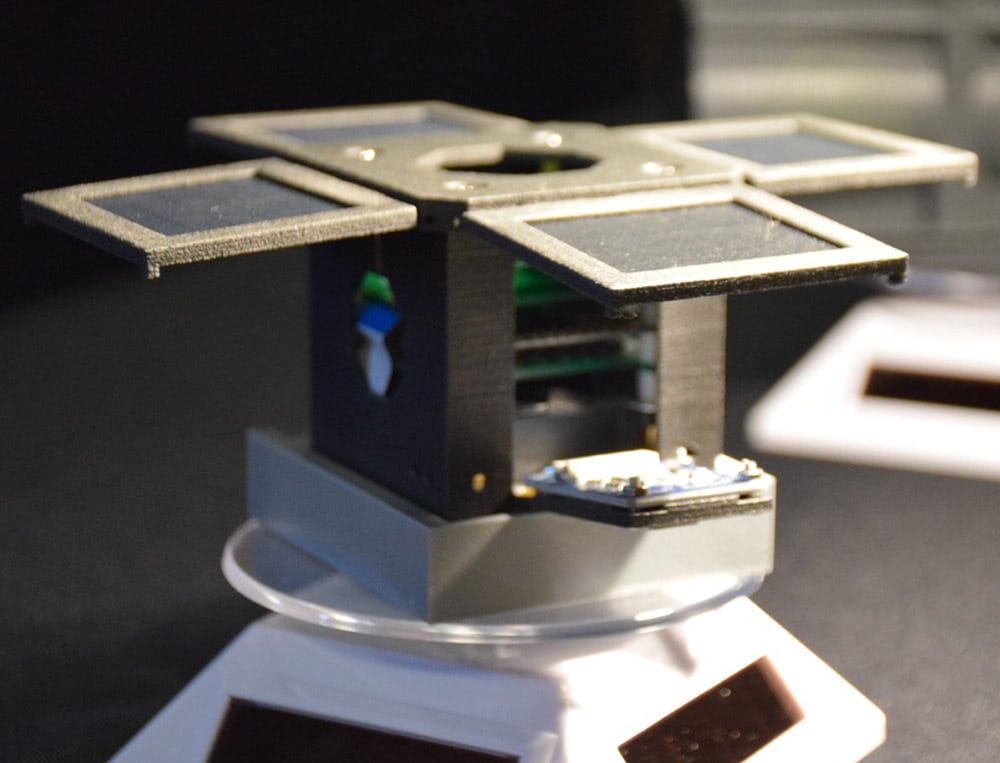

Accurate, reliable, and durable functional prototypesAerospace: small satellites structure, spacecraft componentsAutomotive: cooling ducts, mirrors, headlight coversMotorsports: end plates, fences, alternator coversSmall production and pre-series parts

FEATURES

Excellent strengthHigh stiffnessReduced weightTop level material

Which characteristics

are you searching for?

KEY VALUES

Density (20° C) 1,097 g/ccHDT (1.82 Mpa) 173,4° CTensile Strength 83,84 MpaElongation @ break 3,80 %Melting point 179,3° C

Technical data sheet

DownloadAPPLICATIONS

Accurate, reliable, and durable functional prototypesAerospace: small satellites structure, spacecraft componentsAutomotive: cooling ducts, mirrors, headlight coversMotorsports: end plates, fences, alternator coversSmall production and pre-series parts

Windform successful stories

Get inspiredTechnical Properties

Density: 1,097 g/cc

Colour:

BLACK

| Thermal Properties | Test Method | SI Unit | US Unit |

|---|---|---|---|

| Melting point | ISO 11357-2 | 179,30° C | 355° F |

| HDT, 1.82 Mpa | ISO 75-2 TYPE A | 173,40° C | 344° F |

| Vicat 10N | ISO 306 TYPE A50 | 176,10° C | 349° F |

| Flammability Properties | Test Method | SI Unit | US Unit |

|---|---|---|---|

| Burning Test - HB 1 mm | UL 94 | HB | HB |

| Burning Test - HB 3 mm | UL 94 | HB | HB |

| Mechanical Properties | Test Method | SI Unit | US Unit |

|---|---|---|---|

| Tensile Strength | UNI EN ISO 527-1 | 83,84 Mpa | 12200 psi |

| Tensile Modulus | UNI EN ISO 527-1 | 8928,20 Mpa | 1290 ksi |

| Elongation at Break | UNI EN ISO 527-1 | 3,80 % | 3,80 % |

| Flexural Strength | UNI EN ISO 178 | 133,00 Mpa | 19300 psi |

| Flexural Modulus | UNI EN ISO 178 | 7338,20 Mpa | 1060 ksi |

| Impact Strength Unnotched (Charpy 23 °C/73.4 °F) | UNI EN ISO 179 | 22,43 KJ/m² | 10.7 ft-lb/in² |

| Impact Strength Notched (Charpy 23 °C/73.4 °F) | UNI EN ISO 179 | 4,72 KJ/m² | 2.25 ft-lb/in² |

| Impact Strength Unnotched (Izod 23 °C/73.4 °F) | UNI EN ISO 180 | 19,26 KJ/m² | 9.16 ft-lb/in² |

| Impact Strength Notched (Izod 23 °C/73.4 °F) | UNI EN ISO 180 | 5,30 KJ/m² | 2.52 ft-lb/in² |

| Hardness Shore D | UNI EN ISO 868 | 79 | 79 |

| Poisson Ratio | ASTM D638-14 | 0,41 | 0.41 |

| Compression Strength | ASTM D695-10 | 120,2 Mpa | 17433.54 psi |

| Compression Elastic Modulus | ASTM D695-10 | 6,18 Gpa | 896.33 ksi |

| Electrical Properties | Test Method | SI Unit | US Unit |

|---|---|---|---|

| Resistivity, Volume | ASTM D257 | <10^8 ohm*cm | <10^8 ohm*cm |

| Resistivity, Surface | ASTM D257 | <10^8 ohm | <10^8 ohm |

| Surface Finish | SI Unit | US Unit |

|---|---|---|

| After SLS Process | 6,00 Ra μm | 6.00 Ra μm |

| After manual finishing | 1,8 Ra μm | 1.8 Ra μm |

| Properties per Density Unit | SI Unit | US Unit |

|---|---|---|

| UTS per density unit | 76,43 Mpa/(g/cc) | 11100 psi/(g/cc) |

| Tensile Modulus per density unit | 8138,74 Mpa/(g/cc) | 1180 ksi/(g/cc) |

| Flexural Strength per density unit | 121,24 Mpa/(g/cc) | 17600 psi/(g/cc) |

| Flexural Modulus per density unit | 6689,33 Mpa/(g/cc) | 970 ksi/(g/cc) |

Note: The material properties provided herein are for reference purposes only. Data was generated from the testing of parts produced with Windform XT 2.0 material under optimal processing conditions. Actual values may vary significantly as they are affected by part geometry and process parameters. Material specifications are subject to change without notice.

Standard Technical Details for Accuracy versus Tolerance:

For parts up to 1 mm (0.039″), the standard tolerance is ± 0,070 mm (0.003″)

For parts up to 3 mm (0.118″), the standard tolerance is ± 0,125 mm (0.005″)

For parts up to 6 mm (0.236″), the standard tolerance is ± 0,150 mm (0.006″)

For parts over 6 mm (0.236″), refer to UNI EN ISO 286-2 JS14 class (linear tolerances).

Technical specifications

Windform® XT 2.0 is a ground breaking carbon fiber reinforced composite SLS material known for its high mechanical properties.

This innovative material replaces the previous formula of Windform® XT in the Windform® family of materials, and it features improvements especially in mechanical properties, including: +8% increase in tensile strength, +22% in tensile modulus, and +46% increase in elongation @ break.

Windform® XT 2.0 has been rated HB according to the flammability UL 94 test.

It is skin contact approved.

Applications

It is particularly suitable in demanding applications such as Motorsports, Aerospace, and UAV sectors.

Moreover this cutting edge material for professional 3D printing service – as mainly composite materials from the Windform® TOP-LINE – has passed outgassing tests at the most important Space Agencies, and it’s suitable for space missions.

In fact both CRP Technology and CRP USA have built a considerable experience supplying cutting-edge solutions for space key industry leaders.

The versatility of the Windform® XT 2.0 combined with the technology used, allows for near endless possibilities: it is the material of choice for the creation of accurate, reliable, and durable prototypes and it is perfect for functional applications for the most demanding industries.