3D printed satellite: an introduction

“3D printed satellite” is a term increasingly used in texts describing aerospace experiences, especially when depicted space missions involving small satellites. In fact, more and more often we come across phrases like: “The small satellite or “nanosatellite” revolution is here”.

Kilogram-class satellites, like CubeSats, now have functionality that were only available in larger 100 to 1,000 kg class satellites. Recently, 3D printing has helped speed up this revolution, especially in universities. CubeSats have been launched by dozens of countries, universities and companies all around the world.

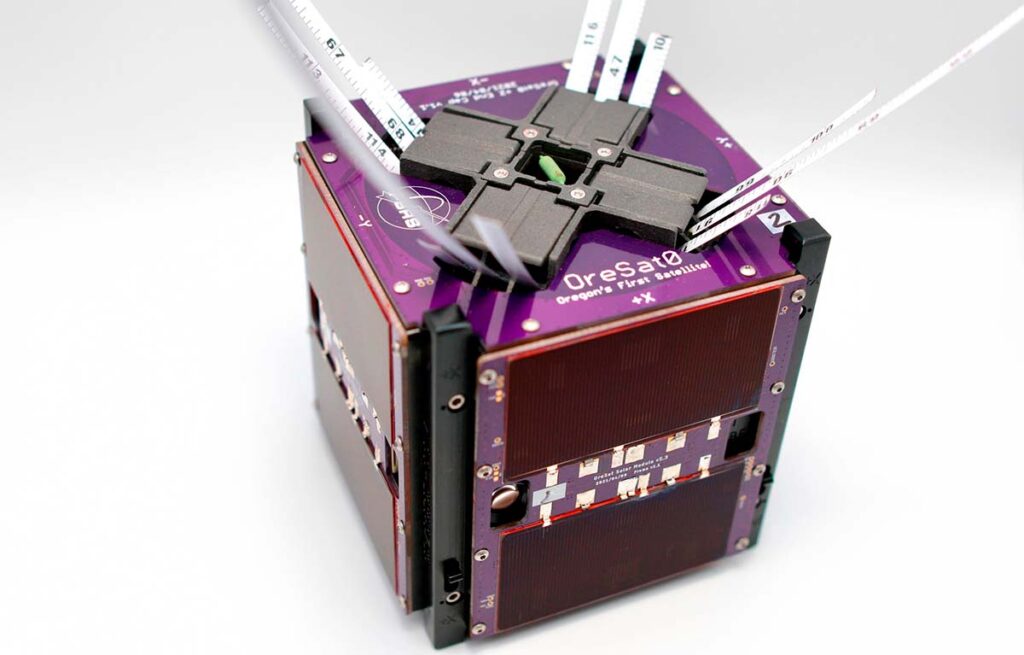

And the state of Oregon joined them recently thanks to the Portland State Aerospace Society (PSAS) that built OreSat0, their very own artisanally hand-crafted CubeSat system, currently in low Earth orbit. This achievement in the field of 3D printed satellite was possible thanks to their use of Windform LX 3.0 composite material and industrial 3D printing in their most critical subsystems. Windform LX 3.0 and 3D printing were supplied by CRP USA.

The OreSat bus project

The Portland State Aerospace Society is an open source, interdisciplinary student aerospace project at Portland State University in Portland, Oregon, with collaborators at most other Oregon universities. They make sophisticated amateur rockets, small liquid fuel rocket engines, and CubeSat nanosatellites.

They currently have three satellite missions in the works. All rely on the fully open source OreSat bus which they are offering as an inexpensive (for a satellite) “DIY” platform for designing and building 1U through 3U CubeSats, paving the way for a solution to the “COTS vs DIY” dilemma.

“OreSat is our fully open source, modular, and re-usable CubeSat system designed for educational teams”, said PSAS members. “OreSat uses a card cage system, which allows cards to be reused on different missions from 1U to 3U CubeSats. Cards include everything you would expect aboard a CubeSat: an on-board computer with multi-band radios, a battery pack, a star tracker, a GPS receiver, and the beginnings of an attitude determination and control system (ADCS). Solar modules are mounted on the outside of the Aluminum frame, along with deployable omnidirectional antennas.”

OreSat0 was deployed into low earth orbit on March 15th, 2021 and has been successfully operating since then. OreSat0.5 is being readied for flight in October 2023, and OreSat1 is scheduled for a deployment off of the international space station in early 2024.

The project

The Portland State Aerospace Society is determined to develop better students through hands-on interdisciplinary systems engineering projects. Everything is designed, built, and tested by interdisciplinary student teams: mechanical engineers work on the structure, thermals, and CAD, Electrical engineers design the cards made of PCBs (standard two and four layers boards), and computer science students program the Linux boxes and microcontrollers that run the CubeSat.

PSAS members added, “There are very few open source satellites in the world, and ours is probably the most fully featured. We are currently collaborating with four other universities who are building satellites and ground stations based on our projects.”

Using industrial 3D Printing and Windform

Before employing Selective Laser Sintering and Windform LX 3.0 for manufacturing subsystems on OreSat0, PSAS members used other technologies. “We designed and manufactured the parts locally using extremely inexpensive FDM machines until we prototyped a design that worked. We then switched to SLS 3D printing, which worked extremely well. But we couldn’t find SLS parts that could stand the temperature extremes and that were vacuum rated to NASA and ESA outgassing standards.

We were absolutely thrilled to find CRP Technology’s Windform LX 3.0 composite material and CRP USA as technology supplier. With Windform LX 3.0, we could design the parts for 3D printing, run quick turns to prototype on local printers, and then print our final engineering and flight units out of Windform.

It absolutely changed the way we design all parts of our satellite thanks to its characteristics: Windform LX 3.0 can be used in space; it has extremely good material properties; it is extremely easy to work with; it is far superior to other 3D printing materials, including the other FDM, SLA, and SLS technologies that we’ve used.”

3D printed parts in Windform LX 3.0, OreSat0’s critical subsystems

The 3D printed parts that CRP USA manufactured for PSAS’s OreSat0 are three critical subsystems. The material chosen was Windform LX 3.0, a glass fiber reinforced material from the Windform TOP-LINE range of SLS composite materials for Powder Bed Fusion 3D printing process (Selective Laser Sintering).

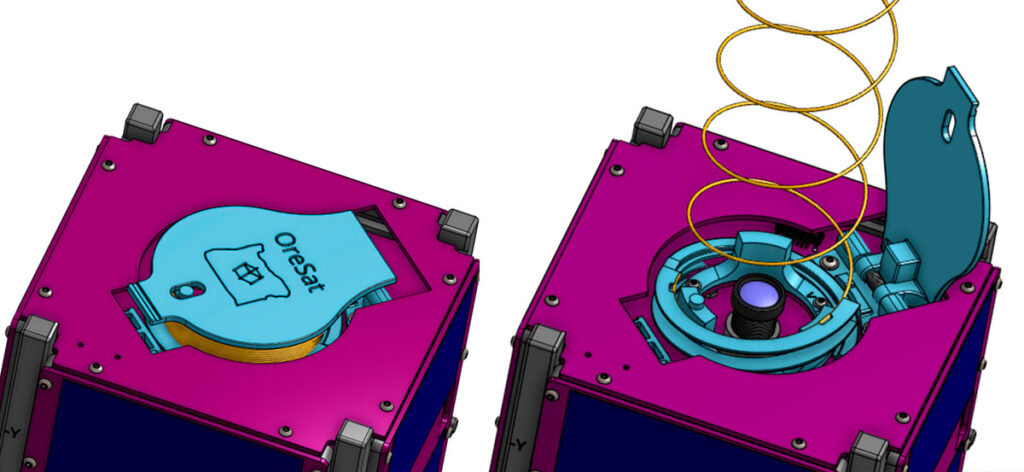

Deployer for the tri-band turnstile antenna

Windform LX 3.0 allowed the PSAS team to use 3D printing processes on their critical subsystems, including their extremely reliable deployer for their tri-band turnstile antenna. The antenna has three separate antennas (UHF at 436.5 MHz, L band at 1.265 GHz, and L1 at 1.575 GHz) each with 4 elements; all 12 of these elements are deployed using nylon monofilament lines and only a single melt resistor.

According to the team, “There was no way we would have been able to get the packing density of three bands with four elements each in anything other than a 3D printed, non-conductive process. We don’t know of any other satellite with this kind of antenna density.”

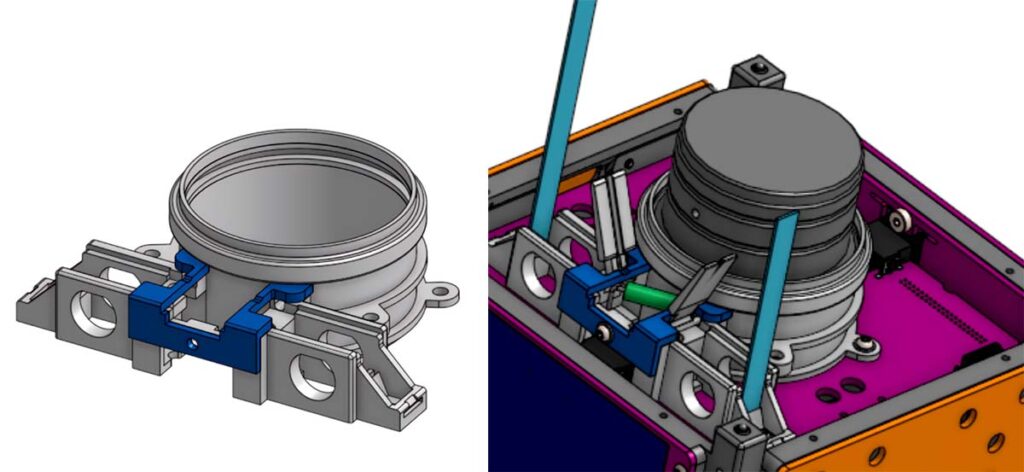

Star Tracker Lens and Sensor Assembly

Using CRP’s Windform LX 3.0, PSAS members were able to mount their star tracker sensor and lens on a small daughterboard that kept the entire assembly to a single 10 mm tall card form factor.

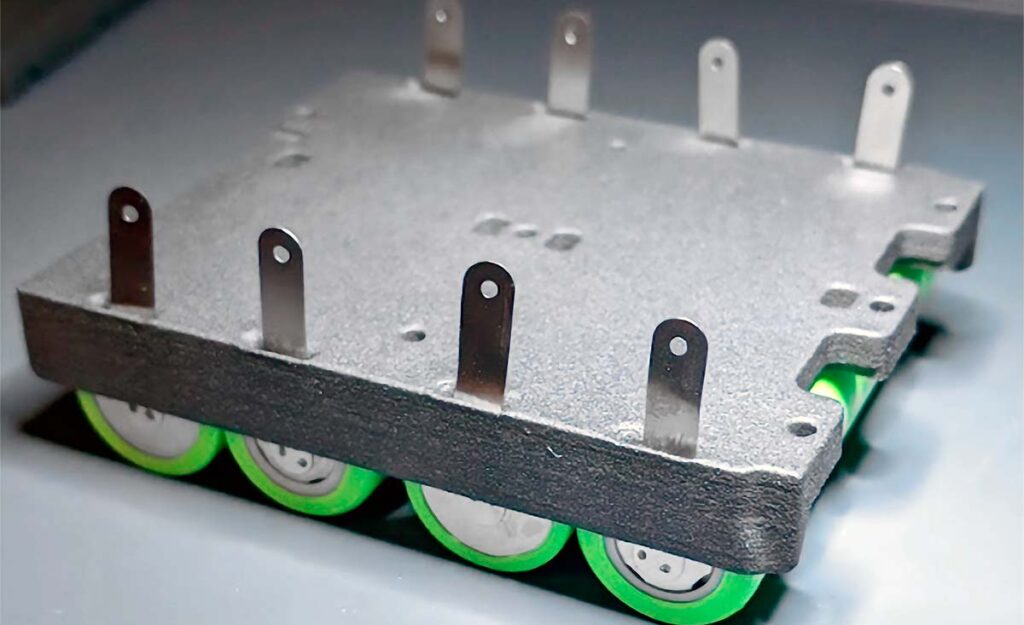

Battery Pack

The battery pack needed to reliably hold 18650 cells through vibration testing while also providing thermal and electrical insulation from the rest of the satellite. Windform LX 3.0 allowed PSAS to make an extremely compact battery assembly that was still extremely rugged.

Testing performed on Windform parts

Before integration into the launch vehicle, OreSat0 (with 3D printed parts in Windform LX 3.0) was subjected to the following testing: Three axis 14 g random vibration, -40 to +80 °C thermal cycling, and vacuum cycling. Windform performed flawlessly for all of these tests.

“A satellite in orbit is exposed to some of the most harsh conditions a system can endure: 14 g of random vibration during launch, the vacuum of space which causes most plastic materials to outgas, and an extreme temperature range from -40 °C (or colder!) to +100 °C (or hotter!).” add PSAS members.

Advantages in using Windform LX 3.0

The PSAS team recognized three crucial advantages by the use of Windform LX 3.0 and industrial 3D printing technology/ Selective Laser Sintering process:

- The SLS process provides robust parts that can take environmental testing, including 14 g of random vibration in all three axes and thermal vacuum cycling from -40 to +80 C.

- The Windform LX 3.0 provides us critical outgassing compliance that’s not available with any other SLS process

- Windform LX 3.0 provides a non-conductive assembly that can be safely used next to electrical components, such as PCBs, batteries, and antennas

According to the students: “Working with nanosatellites means extremely limited volume for all systems, so the ability to evolve and maximize the use of our space has been very beneficial. We pack a lot into a small space, and we can plan to use nearly every cubic millimeter when we can use 3D printed parts.

Committing to the “final” design is always a tricky step – have we thought everything through?? Once we have the part in hand, it is much more difficult to make changes. Luckily, 3D printing is the fastest way to revise parts if something goes wrong.”

Future OreSat Uses For Windform LX 3.0

Windform LX 3.0 is being used to manufacture future OreSat subsystems, including:

Monopole Antenna Deployer

A modified version of OreSat0’s turnstile deployer that use two monopole elements (L band and UHF band) instead of a turnstile antenna. The deployer also provides structural support to the Cirrus Flux Camera lens, a short wave infrared camera mounted next to the deployer.

Helical Antenna Deployer

After the satellite is in orbit, the burn wire allows the door to open and the spring deploys out and into place. Light blue structures are Windform LX 3.0.

You can find out more at Portland State Aerospace Society website.