The transition between the 2012 and 2013 season brought significant change to the DeltaWing. An entirely new operating team, crew, engine, and tire partner made for several new elements as the team took to the track. There is very little time between races to make necessary changes to a car, and the DeltaWing Racing Cars team and Élan Motorsports were faced with having to design a new engine from scratch.

Understanding the design and time constraints, when it came to the intake manifold, design engineer Christian “Skitter” Yaeger, turned to CRP USA to assist on the design and production.

The result of their combined efforts: from nothing but a Mazda head to a new running engine in 81 days, to racing at Sebring in 105 days – including a 3D printed intake manifold.

DeltaWing Innovative Design and Additive Manufacturing

The introduction of the DeltaWing in 2010 brought radical innovation and progressing efficiency to the racetrack. When the DeltaWing took to the racetrack, the engineering team pushed the boundaries of conventional design and launched a revolutionary approach in motorsports. Yet, it is with the new DeltaWing that took to the track in 2013, that is pushing the boundaries of efficiency, technology and innovation.

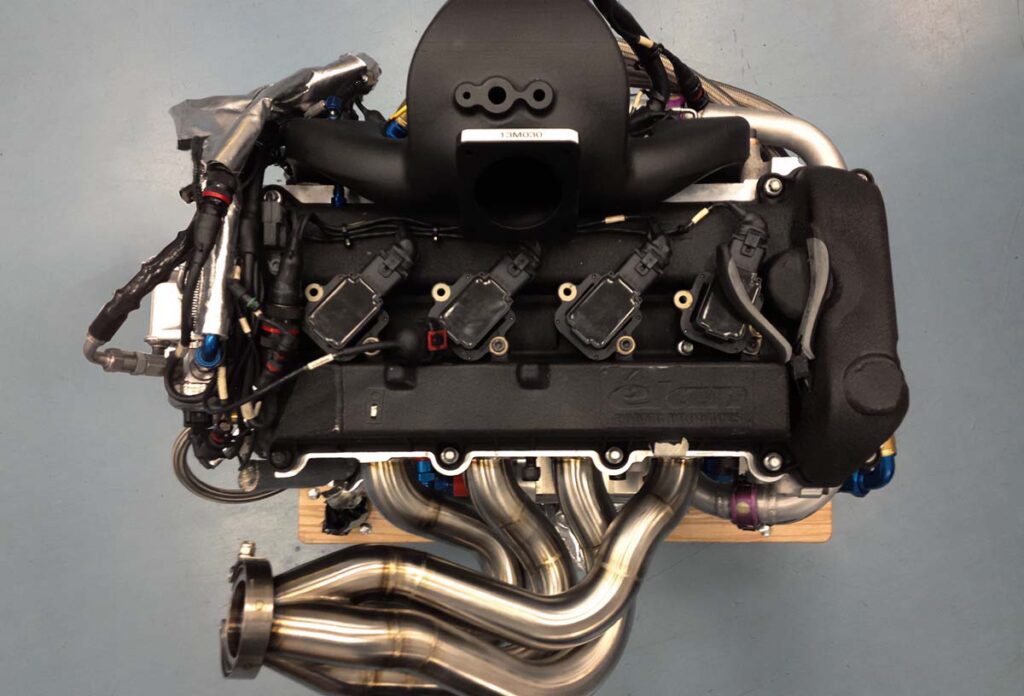

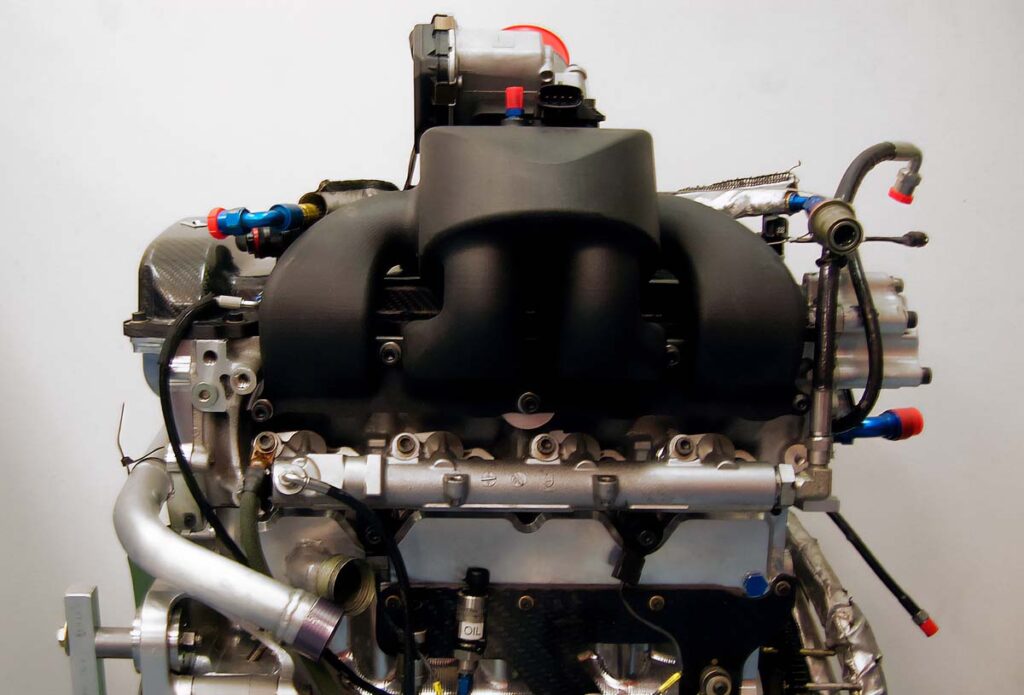

Engineers at DeltaWing Racing Cars, working with CRP USA and Windform, created a component that is fully functional in the race industry. The result was an intake manifold designed and developed by DeltaWing Racing Cars utilizing 3D Printing technology with Windform SP for its construction, to operate under boost utilized in race conditions.

The resulting component has been campaigned by the team since March 2013, gaining positive results and showing the tremendous potential for utilizing advanced materials technologies in partnership with 3D Printing.

One Step Process: Direct from CAD to Part

The DeltaWing Intake Manifold is 3d printed on CRP USA’s additive manufacturing SLS technology. Produced in Windform SP the intake manifold is mounted directly to engine. DeltaWing Racing Cars have run 4 copies of the intake since July 2013.

The manifolds have covered over 12,000 testing and racing miles, along with 6 hours per unit running on the dyno.

“We could not have made this motor happen if we couldn’t produce parts directly from CAD files,” said Christian “Skitter” Yaeger, design engineer for DeltaWing Racing Cars. “The biggest benefit is being able to print exactly what you need. We have eight odd-shaped ports in the head, and CRP USA was able to match them perfectly, with a knife edge in between.”

“With the coupe version, we went slightly less wild, and a little more conventional in our design,” continued Skitter. “Over the past two years, the 3D Printed manifolds have covered over 12,000 testing and racing miles, along with 6 hours per unit running on the dyno.”

Material Strength Ideal for Racing Conditions

Prior to the production of the intake manifold, Windform was used on the DeltaWing to produce several different components such as electronics enclosures, and transmission seal covers with integrated, pressurized oil feed passages.

As the engineering began the redesign of the intake manifold, a high performance material was required to handle the heat and tension placed on the part. CRP USA introduced Windform SP to the DeltaWing engineering team for consideration. Windform SP is a composite polyamide based carbon-filled SLS material.

Windform SP has excellent mechanical properties and an added advantage of increased resistance to shocks, vibrations, deformations, and most importantly, Windform SP is resistant to absorption of liquids and moisture.

Engine Facts

- Weight: 180lbs

- Block machined from billet in house

- Block designed from scratch in 17 days

- From nothing but a Mazda head to a running engine in 81 days, to racing at Sebring in 105 days

“The packaging constraints required by the location of the engine within the chassis requires some creative design,” said Stewart Davis, Director of Operations, CRP USA. “The runner lengths attach at the base of the plenum and form a complex structure that would be extremely difficult to build without using additive manufacturing. Windform SP’s toughness and heat deflection temperature allow the part to be built and then raced in the endurance series.

The engine is run under boost, so it sees pressure variation in addition to the vibration, shock, and temperatures changes associated with racing.”

“The work done by Skitter and the DeltaWing/Élan Motorsports team is a great example of the application of Windform for a complex problem, and utilizing Additive Manufacturing to push the boundaries in racing,” concluded Davis.

Since its introduction in March 2013, below are the tracks where the intake manifold covered 12,000 racing and testing miles:

2013 American Le Mans Series

- Sebring International Raceway

- Mazda Raceway Laguna Seca

- Lime Rock Park

- Canadian Tire Motorsport Park

- Road America

- Circuit Of The Americas

- Virginia International Raceway

- Road America

2014 TUDOR United SportsCar Championship

- Daytona International Speedway

- Sebring International Raceway

- Mazda Raceway Laguna Seca

- Watkins Glen International

- Canadian Tire Motorsport Park

- Road America

- Road Atlanta

About DeltaWing Racing Cars

Boasting half the weight, horsepower and aerodynamic drag of its competition, the radically innovative DeltaWing prototype ushers in a new era of sustainability in motorsports. The DeltaWing represents a major step forward in decreasing motorsport’s carbon footprint; its unique aerodynamic design dramatically reduces the amount of fuel and tires used during a race weekend and gives the car excellent straight line speed. Catch the DeltaWing Racing Cars team competing in the Prototype class in the TUDOR United SportsCar Championship.