Class of Material

Polyammide Material Glass Fiber Filled

Technology

High Speed Sintering (HSS)

FEATURES

Excellent stiffness and high tensile strength combined togetherFaster production higher volumes at lower costHigher stiffness compared to Windform P1Insulated material (CTI rating of 600)

KEY VALUES

Density (20° C) 1,14 g/ccHDT (1.82 Mpa) 126° CUTS Tensile Strength (X axis) 39,24 MpaElongation @ break (X axis) 4,84%Tensile Modulus (X axis) 2925,20 MpaFlexural Modulus 2519 MpaComparative Tracking Index 600

APPLICATIONS

Automotive: rigid parts for interior designConsumer and household goodsElectronics enclosures and housing for electronicsIndustrial products: furniture parts, fixtures and tooling

FEATURES

Excellent stiffness and high tensile strength combined togetherFaster production higher volumes at lower costHigher stiffness compared to Windform P1Insulated material (CTI rating of 600)

Which characteristics

are you searching for?

KEY VALUES

Density (20° C) 1,14 g/ccHDT (1.82 Mpa) 126° CUTS Tensile Strength (X axis) 39,24 MpaElongation @ break (X axis) 4,84%Tensile Modulus (X axis) 2925,20 MpaFlexural Modulus 2519 MpaComparative Tracking Index 600

Technical data sheet

DownloadAPPLICATIONS

Automotive: rigid parts for interior designConsumer and household goodsElectronics enclosures and housing for electronicsIndustrial products: furniture parts, fixtures and tooling

Windform successful stories

Get inspiredTechnical Properties

Density: 1,14 g/cc

Colour:

DARK GREY

| Thermal Properties | Test Method | SI Unit | US Unit |

|---|---|---|---|

| Melting point | ISO 11357 | 181,30° C | 358.34° F |

| HDT, 1.82 Mpa | ISO 75 Method A | 126,00° C | 258.80° F |

| Vicat 10N | ISO 306 Method A50 | 175,50° C | 347.90° F |

| Mechanical Properties | Test Method | SI Unit | US Unit |

|---|---|---|---|

| Tensile Strength - X axis | UNI EN ISO 527-1 | 39,24 Mpa | 5691.28 psi |

| Tensile Strength - Y axis | UNI EN ISO 527-1 | 36,18 Mpa | 5247.46 psi |

| Tensile Strength - Z axis | UNI EN ISO 527-1 | 33,42 Mpa | 4847.16 psi |

| Tensile Modulus - X axis | UNI EN ISO 527-1 | 2925,20 Mpa | 424.26 ksi |

| Tensile Modulus - Y axis | UNI EN ISO 527-1 | 2429,00 Mpa | 352.30 ksi |

| Tensile Modulus - Z axis | UNI EN ISO 527-1 | 2449,60 Mpa | 355.28 ksi |

| Elongation at Break - X axis | UNI EN ISO 527-1 | 4,84 % | 4.84 % |

| Elongation at Break - Y axis | UNI EN ISO 527-1 | 5,98 % | 5.98 % |

| Elongation at Break - Z axis | UNI EN ISO 527-1 | 2,58 % | 2.58 % |

| Flexural Strength | UNI EN ISO 14125 | 64,32 Mpa | 9328.83 psi |

| Flexural Modulus | UNI EN ISO 14125 | 2519,00 Mpa | 365.35 ksi |

| Impact Strength Unnotched (Charpy 23 °C/73.4 °F) | UNI EN ISO 179-1 | 12,70 KJ/m² | 6.04 ft-lb/in² |

| Impact Strength Unnotched (Charpy -40 °C/-40 °F) | UNI EN ISO 179-1 | 11,90 KJ/m² | 5.66 ft-lb/in² |

| Impact Strength Notched (Charpy 23 °C/73.4 °F) | UNI EN ISO 179-1 | 3,50 KJ/m² | 1.67 ft-lb/in² |

| Impact Strength Notched (Charpy -40 °C/-40 °F) | UNI EN ISO 179-1 | 3,70 KJ/m² | 1.76 ft-lb/in² |

| Hardness Shore D | UNI EN ISO 868 | 77 | 77 |

| Electrical Properties | Test Method | SI Unit | US Unit |

|---|---|---|---|

| Resistivity, Volume | ASTM D257-14 | 2,8 x 10^14 ohm*cm | 2.8 x 10^14 ohm*cm |

| Resistivity, Surface | ASTM D257-14 | 2,2 x 10^15 ohm | 2.2 x 10^15 ohm |

| CTI Comparative Tracking Index | IEC 60112 Solution A | 600 Volt | 600 Volt |

| Surface Finish | SI Unit | US Unit |

|---|---|---|

| After HSS Process | 3,78 Ra μm | 3.78 Ra μm |

| After manual finishing | 2,23 Ra μm | 2.23 Ra μm |

| After CNC machining | 0,67 Ra μm | 0.67 Ra μm |

| Properties per Density Unit | SI Unit | US Unit |

|---|---|---|

| UTS per density unit | 34,42 Mpa/(g/cc) | 4992.20 psi/(g/cc) |

| Tensile Modulus per density unit | 2565,96 Mpa/(g/cc) | 372.16 ksi/(g/cc) |

| Flexural Strength per density unit | 56,42 Mpa/(g/cc) | 8183.02 psi/(g/cc) |

| Flexural Modulus per density unit | 2209,65 Mpa/(g/cc) | 320.48 ksi/(g/cc) |

Note: The material properties provided herein are for reference purposes only. Data was generated from the testing of parts produced with Windform P2 material under optimal processing conditions. Actual values may vary significantly as they are affected by part geometry and process parameters. Material specifications are subject to change without notice.

Standard Technical Details for Accuracy versus Tolerance:

For parts up to 1 mm (0.039″), the standard tolerance is ± 0,070 mm (0.003″)

For parts up to 3 mm (0.118″), the standard tolerance is ± 0,125 mm (0.005″)

For parts up to 6 mm (0.236″), the standard tolerance is ± 0,150 mm (0.006″)

For parts over 6 mm (0.236″), refer to UNI EN ISO 286-2 JS14 class (linear tolerances).

Technical specifications

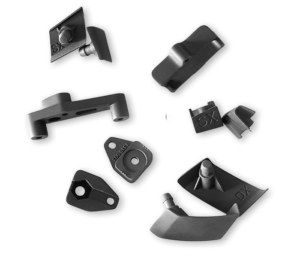

Windform® P2 is the second material from P-LINE, the new born range dedicated to high speed production-grade 3D Printing technology.

It is a thermoplastic glass fiber filled material with optimal mechanical properties (higher stiffness compared to Windform® P1).

Windform® P2 offers excellent stiffness and high tensile strength combined together.

Applications

Windform® P2 has been engineered for a faster production of functional prototypes, end-use parts requiring high stiffness across a variety of sectors. Just to indicate some examples of applications: Electrical (enclosures and housing for electronics); Consumer and household goods; Industrial products (furniture parts, presentation models, fixtures and tooling); Automotive (rigid parts for interior design).

It is suitable for the manufacturing of components with detailed resolution.