Class of Material

Glass fiber filled composite material polyamide based

Technology

Selective Laser Sintering

FEATURES

Electrical insulation materialExcellent elasticity and flexibilityHigh resistance to impactSkin contact approvedWaterproof

KEY VALUES

Density (20° C) 1,19 g/ccHDT (1.82 Mpa) 169,4° CTensile Strength 56,21 MpaElongation @ break 14,82 %Melting point 193,0° C

APPLICATIONS

Automotive: snap fit components, high flexible partsMedical: tailor-made orthoses and insoles, prosthetic coversMotorsports: air and hydraulic ducts, protective coversParts requiring flexibility combined to resistance to impact

FEATURES

Electrical insulation materialExcellent elasticity and flexibilityHigh resistance to impactSkin contact approvedWaterproof

Which characteristics

are you searching for?

KEY VALUES

Density (20° C) 1,19 g/ccHDT (1.82 Mpa) 169,4° CTensile Strength 56,21 MpaElongation @ break 14,82 %Melting point 193,0° C

Technical data sheet

DownloadAPPLICATIONS

Automotive: snap fit components, high flexible partsMedical: tailor-made orthoses and insoles, prosthetic coversMotorsports: air and hydraulic ducts, protective coversParts requiring flexibility combined to resistance to impact

Windform successful stories

Get inspiredTechnical Properties

Density: 1,19 g/cc

Colour:

BLACK

| Thermal Properties | Test Method | SI Unit | US Unit |

|---|---|---|---|

| Melting point | ISO 11357-2 | 193,0° C | 379° F |

| HDT, 1.82 Mpa | ASTM D 648 TYPE B | 169,4° C | 337° F |

| Vicat 10N | ASTM D1525-09 | 188,9° C | 372° F |

| Flammability Properties | Test Method | SI Unit | US Unit |

|---|---|---|---|

| Burning Test - HB 1 mm | UL 94 | HB | HB |

| Burning Test - HB 3 mm | UL 94 | HB | HB |

| Mechanical Properties | Test Method | SI Unit | US Unit |

|---|---|---|---|

| Tensile Strength | UNI EN ISO 527-1 | 56,21 Mpa | 8150 psi |

| Tensile Modulus | UNI EN ISO 527-1 | 3289,80 Mpa | 477 ksi |

| Elongation at Break | UNI EN ISO 527-1 | 14,82% | 14.82% |

| Flexural Strength | UNI EN ISO 14125 | 87,90 Mpa | 12700 psi |

| Flexural Modulus | UNI EN ISO 14125 | 3227 Mpa | 468 ksi |

| Impact Strength Unnotched (Charpy 23 °C/73.4 °F) | UNI EN ISO 179-1 | 54,28 KJ/m² | 25.8 ft-lb/in² |

| Impact Strength Notched (Charpy 23 °C/73.4 °F) | UNI EN ISO 179-1 | 8,69 KJ/m² | 4.14 ft-lb/in² |

| Hardness Shore D | UNI EN ISO 868 | 79 | 79 |

| Compression Strength | ASTM D695-10 | 90,8 Mpa | 13169.43 psi |

| Compression Elastic Modulus | ASTM D695-10 | 4,00 Gpa | 580.15 ksi |

| Electrical Properties | Test Method | SI Unit | US Unit |

|---|---|---|---|

| Resistivity, Volume | ASTM D257-14 | 2,62 x 10^15 ohm*cm | 2,62 x 10^15 ohm*cm |

| Resistivity, Surface | ASTM D257-14 | 1.02 x 10^16 ohm | 1.02 x 10^16 ohm |

| Surface Finish | SI Unit | US Unit |

|---|---|---|

| After SLS Process | 6,20 Ra μm | 6,20 Ra μm |

| After manual finishing | 1,45 Ra μm | 1,45 Ra μm |

| After CNC machining | 1,15 Ra μm | 1,15 Ra μm |

| Properties per Density Unit | SI Unit | US Unit |

|---|---|---|

| UTS per density unit | 47,24 Mpa/(g/cc) | 6850 psi/(g/cc) |

| Tensile Modulus per density unit | 2764,54 Mpa/(g/cc) | 401 ksi/(g/cc) |

| Flexural Strength per density unit | 73,87 Mpa/(g/cc) | 10700 psi/(g/cc) |

| Flexural Modulus per density unit | 2711,76 Mpa/(g/cc) | 393 ksi/(g/cc) |

Note: The material properties provided herein are for reference purposes only. Data was generated from the testing of parts produced with Windform GT material under optimal processing conditions. Actual values may vary significantly as they are affected by part geometry and process parameters. Material specifications are subject to change without notice.

Standard Technical Details for Accuracy versus Tolerance:

For parts up to 1 mm (0.039″), the standard tolerance is ± 0,070 mm (0.003″)

For parts up to 3 mm (0.118″), the standard tolerance is ± 0,125 mm (0.005″)

For parts up to 6 mm (0.236″), the standard tolerance is ± 0,150 mm (0.006″)

For parts over 6 mm (0.236″), refer to UNI EN ISO 286-2 JS14 class (linear tolerances).

Technical specifications

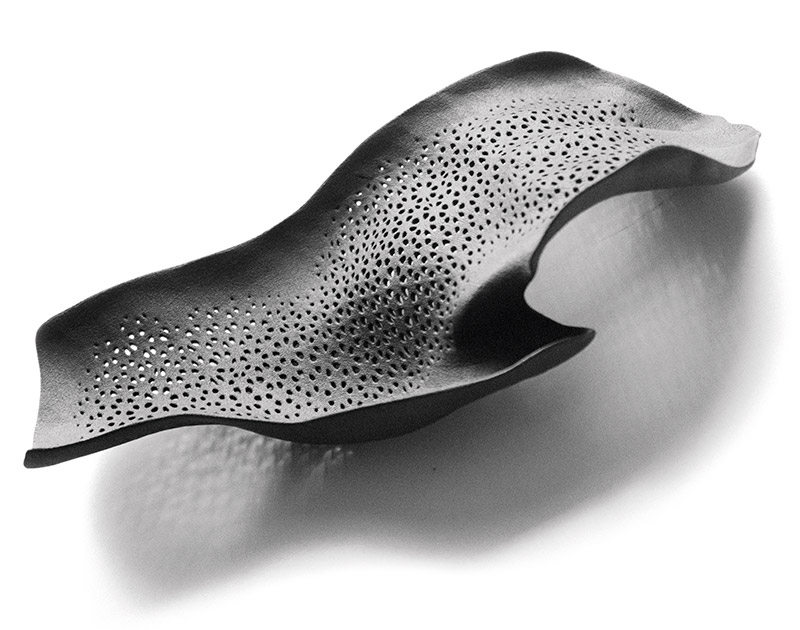

Windform® GT is a polyamide based glass fiber reinforced composite material with a dark black color. After hand polishing, the material is smooth with a deep lustrous finish.

It is a flexible product in the Windform® family of TOP-LINE SLS materials for Additive Manufacturing, not only aesthetically, but also in terms of performance. In fact it combines the optimal characteristics of elasticity, ductility, and resistance to impact.

Windform® GT is also a waterproof material, with resistance to the absorption of moisture and liquids. It is also very light with excellent mechanical properties per unit density. Moreover Windform® GT is not an electrically conductive material.

It has been rated HB according to the flammability UL 94 test and has passed outgassing tests for space missions.

Applications

Windform® GT can be considered a highly valuable material in various and functional applications in regards to vibration and shock (for example: racing components near the ground and under the hood).

The material’s superior values in regards to impact strength and elongation at break, combined with its tensile and flexural strength, make it ideal for applications where resistance to damage is a prerequisite in order to preserve internal components in the event of impact and/or improper use.

Its waterproof characteristics make it particularly suitable for many applications such as air ducts, intake and cooling systems, hydraulic ducts in contact with liquids or oils.

All these applications indicated above are just examples.

You might be also interested in

Glass-fiber filled composite material with good stiffness and electrically insulated

Flame Retardant composite polyamide based material glass fiber filled with insulating properties