Origins

Home / Origins

25+ years of success and reliability offering a technological competitive gap

Windform® is renomated for its outstanding mechanical properties letting designers and engineers realize functional components for small production batches and limited editions with confidence and an eye ahead.

Windform® has been backing up all the organizations and manufacturers in the most advanced sectors.

Nowadays the range encompasses two lines:

Milestones

Windform form of the wind

Rapid casting

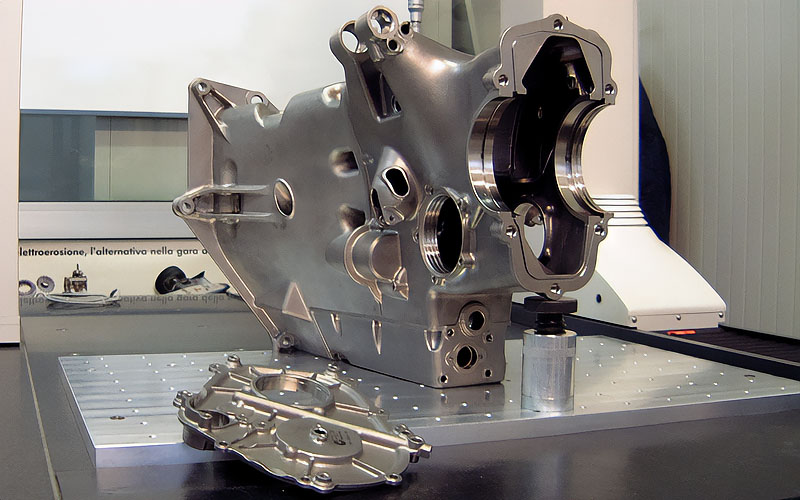

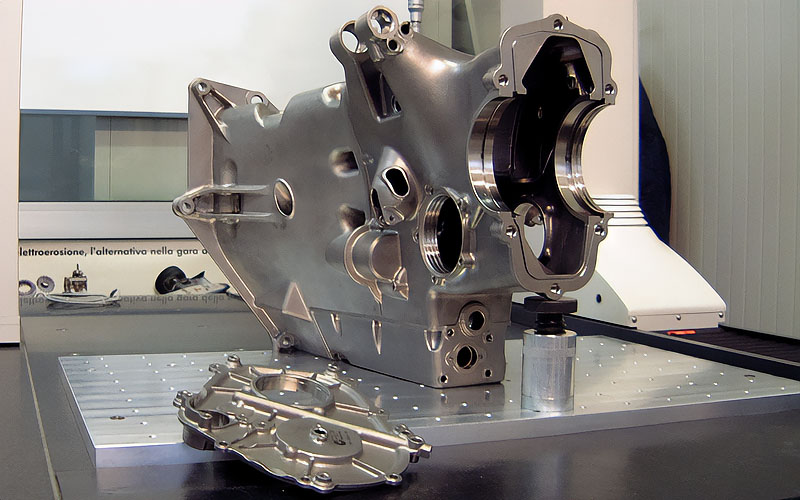

Castform PS material was developed in cooperation with DTM Corp, for the creation of disposable patterns for Titanium Rapid Casting. The goal was to use rapid casting and the best available alloy (Ti-6Al4V) for very high-performance parts with very complicated shapes and geometries.

This represented a major step forwards in the design and product development by shortening the processes, improving the quality and reliability of the parts, to the point of manufacturing in 2000 the first Titanium rapid casting F1 gearbox.

Leader in the Motorsport industry

The evolution from Rapid Prototyping to Rapid Manufacturing

CRP Technology enabled SLS technology to make the big step forward: from Rapid Prototyping applications to Rapid Manufacturing. CRP Technology bridged the gap launching in 2004 Windform XT, the first Carbon fiber filled polymeric material, representing an unique technological achievement expressly for the creation of functional parts via laser sintering technology.

Windform XT 2.0

Windform GF 2.0

Aerospace

Windform materials are strategical innovators into the Aerospace industry thanks to their increased design flexibility, high-mechanical performances, long lasting durability, resistance to UV, together with accuracy in complex and miniaturized parts realization.

They passed the severe outgassing tests of main Space agencies such as NASA (ASTM E-595-07 standard), ESA (TEC-QTE 7171, based on ECSS-Q-ST-70-02C).

CRP Technology pioneered new generation of space applications with the production of functional, space-ready components building up a considerable specialistic experience as provider of cutting edge solutions to best-in-class space leaders.

WINDFORM GT

WINDFORM SP

WINDFORM FX BLACK

WINDFORM LX 3.0

WINDFORM RL

Pushing the technology to its limit

Using Windform materials for functional production-grade models, not just aesthetic ones, was the big challenge.

The R&D department was empowered with this scope. It started to work hard on the materials side, generating new Windform materials with utmost mechanical performances suited to accomplish the specific, extreme and evolving needs of the most demanding industries.

Birth of Windform® P-LINE for HSS technology

The launch of Flame retardant era

Windform RS

Windform XT 2.0 IMG for Injection Moulding

Windform TPU

Windform SL

Windform and the CRP network

Windform composites were created by CRP Technology to maximize the potential of Selective Laser Sintering, and to provide both functional prototypes and products suitable to meet the needs of the most advanced industrial sectors.

Windform materials are being used with great success by CRP USA in the North American market and by CRP GULF in the GCC and UAE market.

As part of the CRP network, CRP Meccanica contributes with its expertise in high-precision CNC machining and mechanical finishing of Windform parts, ensuring tight tolerances and optimal performance for critical applications.