Class of Material

Polyamide based material

Technology

Selective Laser Sintering

FEATURES

Behavior similar to polypropylene and ABS injection moulded partsExcellent surface finish in its sintered stateGood reproduction of finest detailsResistant to impact even at low temperaturesResistant to repeated bending and torsion

KEY VALUES

Density (20° C) 1,022 g/ccHDT (1.82 Mpa) 52,1° CElongation @ break 50,30 %Melting point 198,7° CAfter manual finishing 1,60 Ra μm

APPLICATIONS

Complex-shaped ductingFlexible componentsFunctional parts with living hinges or clip fittingsThin-walled connectors with snap-fit systems

FEATURES

Behavior similar to polypropylene and ABS injection moulded partsExcellent surface finish in its sintered stateGood reproduction of finest detailsResistant to impact even at low temperaturesResistant to repeated bending and torsion

Which characteristics

are you searching for?

KEY VALUES

Density (20° C) 1,022 g/ccHDT (1.82 Mpa) 52,1° CElongation @ break 50,30 %Melting point 198,7° CAfter manual finishing 1,60 Ra μm

Technical data sheet

DownloadAPPLICATIONS

Complex-shaped ductingFlexible componentsFunctional parts with living hinges or clip fittingsThin-walled connectors with snap-fit systems

Windform successful stories

Get inspiredTechnical Properties

Density: 1,022 g/cc

Colour:

BLACK

| Thermal Properties | Test Method | SI Unit | US Unit |

|---|---|---|---|

| Melting point | ISO 11357 | 198,7 °C | 389.66 °F |

| HDT, 1.82 Mpa | ASTM D 648 TYPE B | 52,1 °C | 125.78 °F |

| Vicat 10N | ASTM D1525-09 | 190,5 °C | 374.90 °F |

| Mechanical Properties | Test Method | SI Unit | US Unit |

|---|---|---|---|

| Elongation at Break | UNI EN ISO 527-1 | 50,74 Mpa | 7357.30 psi |

| Elongation at Break | UNI EN ISO 527-1 | 1908,00 Mpa | 276.66 ksi |

| Elongation at Break | UNI EN ISO 527-1 | 50,30 % | 50,30 % |

| Flexural Strength | UNI EN ISO 14125 | 67,60 Mpa | 9802.00 psi |

| Flexural Modulus | UNI EN ISO 14125 | 1820,00 Mpa | 263.90 ksi |

| Elongation at Break | UNI EN ISO 179-1 | 254,35 KJ/m² | 120.94 ft-lb/in² |

| Elongation at Break | UNI EN ISO 179-1 | 217,55 KJ/m² | 103.45 ft-lb/in² |

| Elongation at Break | UNI EN ISO 179-1 | 21,69 KJ/m² | 10.31 ft-lb/in² |

| Elongation at Break | ASTM D638-14 | 4,22 KJ/m² | 2.00 ft-lb/in² |

| Electrical Properties | Test Method | SI Unit | US Unit |

|---|---|---|---|

| Resistivity, Volume | ASTM D257-14 | 3,7x10^15 ohm*cm | 3.7x10^15 ohm*cm |

| Resistivity, Surface | ASTM D257-14 | 9,7x10^15 ohm | 9.7x10^15 ohm |

| Surface Finish | SI Unit | US Unit |

|---|---|---|

| After SLS Process | 5,00 Ra μm | 5.00 Ra μm |

| After manual finishing | 1,60 Ra μm | 1.60 Ra μm |

| After CNC machining | 0,80 Ra μm | 0.80 Ra μm |

| Properties per Density Unit | SI Unit | US Unit |

|---|---|---|

| UTS per density unit | 49,65 Mpa/(g/cc) | 7198.92 psi/(g/cc) |

| Tensile Modulus per density unit | 1866,93 Mpa/(g/cc) | 270.70 ksi/(g/cc) |

| Flexural Strength per density unit | 66,14 Mpa/(g/cc) | 9591 psi/(g/cc) |

| Flexural Modulus per density unit | 1780,82 Mpa/(g/cc) | 258.22 ksi/(g/cc) |

Note: The material properties provided herein are for reference purposes only. Data was generated from the testing of parts produced with Windform FX BLACK material under optimal processing conditions. Actual values may vary significantly as they are affected by part geometry and process parameters. Material specifications are subject to change without notice.

Standard Technical Details for Accuracy versus Tolerance:

For parts up to 1 mm (0.039″), the standard tolerance is ± 0,070 mm (0.003″)

For parts up to 3 mm (0.118″), the standard tolerance is ± 0,125 mm (0.005″)

For parts up to 6 mm (0.236″), the standard tolerance is ± 0,150 mm (0.006″)

For parts over 6 mm (0.236″), refer to UNI EN ISO 286-2 JS14 class (linear tolerances).

Technical specifications

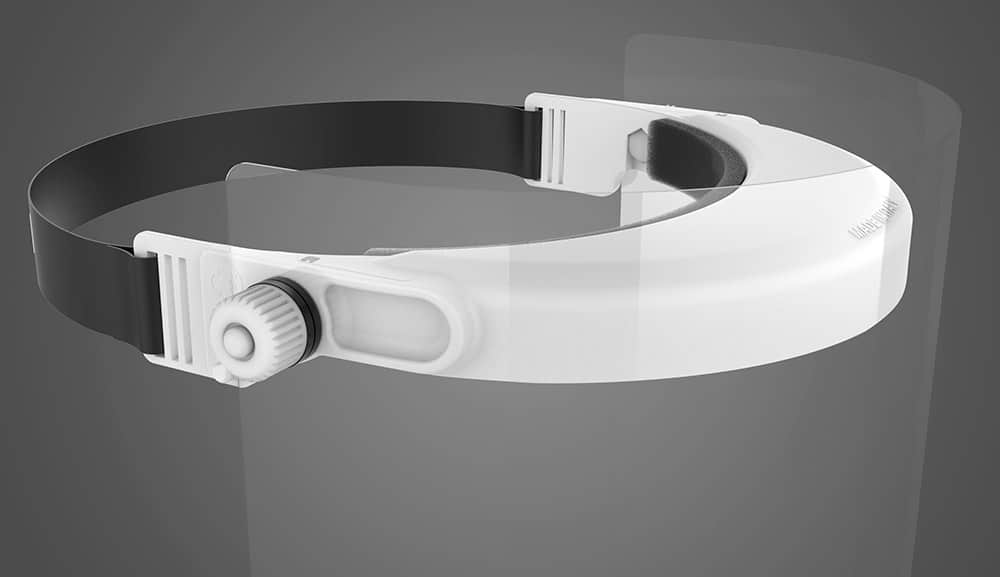

Windform® FX BLACK is a new generation polyamide based SLS material with a dark black color.

It guarantees consistent performance on repeatable jobs.

Windform® FX BLACK is characterized by high flexibility and exceptional resistance to repeated bending and torsion.

The material shows excellent impact resistance even at low temperatures.

Its consistency and behavior are similar to polypropylene and ABS injection moulded parts.

Applications

Windform® FX BLACK is perfect for creating accurate, reliable, and functional prototypes.

It can be considered a highly valuable material in various end use applications when flexibility and strength cannot be compromised, for example: parts with living hinges or clip fittings, ducting of complex shapes, thin walled connectors with snap-fit systems.